The purpose of automobile bumpers is to remain intact while absorbing low-speed impacts and to protect body panels from any damage. Traditionally, bumpers that accomplished this task were chrome-covered steel bars bolted onto a vehicle’s front and rear. Today’s vehicles still have an actual metal bumper beam, but it’s structural only and lighter in weight. A plastic piece known as a bumper cover fits over that structural beam, and is typically painted to provide a seamless look on the front or rear of a vehicle. In between a bumper cover and reinforcement beam (made of steel or aluminum), you’ll find additional impact-absorbing materials such as Styrofoam or plastic honeycomb mesh. In this article, we’ll cover a brief history of bumpers and bumper covers, how to perform minor repairs to plastic bumper covers, and how to remove and replace a bumper cover should repairs be impractical.

HISTORY OF U.S. FEDERAL BUMPER REGULATIONS

Long before plastic bumper covers became the norm, the new-for-1968 Pontiac GTO featured a revolutionary plastic nose cap that doubled as an impact-absorbing bumper.

Until the 1973 model year, there were no standards governing how much protection bumpers provided. Form over function often ruled in design studios, leaving consumers with expensive repairs after stylish bumper pieces provided little damage protection. The United States Federal Motor Vehicle Safety Standard No. 215 mandated 1973 model year bumpers must be strong enough to prevent headlights, tail lights, fuel system components, and other safety items from damage after a 5 mile-per-hour frontal impact and 2.5 mile-per-hour rear impact.

Chevrolet Corvettes were early adopters of plastic end caps to cover more massive steel bumpers required to meet federal regulations. Corvettes got plastic bumper covers in front for 1973, and on the rear for 1974 (1974 model shown).

For the 1974 model year, front and rear bumpers were required to protect lights, engine, and safety systems from 5 mph impacts tests that were now performed at an angle. Regulations were upped further on 1979 models, stating that all body panels must be protected from any damage in 5 mph tests instead of just lights. Finally, the toughest standards were put into place during 1980-82 model years, which limited damage the bumpers themselves were allowed to sustain. A new requirement stating all bumpers must be mounted between 16 and 20 inches above the ground was added as well. For the 1983 model year, requirements were dropped back to 2.5 mph on front and rear straightforward barrier tests and 3 mph on corner impact tests. Bumpers and attachments could again be damaged as long as body panels and lights were unaffected.

REGULATIONS AFFECTED BUMPER DESIGN TRENDS.

For the 1974 model year, front and rear bumpers were required to protect lights, engine, and safety systems from 5 mph impacts tests performed at an angle. Bumpers became noticeably larger and were mounted further from the vehicle with shock absorbers that allowed more compression. (1975 AMC Matador coupe shown)

1973 regulations requiring lights remain free from damage in bumper tests led to a change. Turn signal lights and taillights that had previously been integrated into the bumper design were relocated onto the body out of necessity, and manufacturers used either permanently fixed bumper designs with solid rubber guards or bumpers designed to retract through the use of telescoping shock absorbers.

Once bumpers needed to withstand harder impacts and from an angle in 1974, steel bumpers were made larger and sturdier to accomplish this. Energy absorption requirements usually forced engineers to mount them further away from the vehicle to provide clearance for larger mounts and shock absorbers. Compare virtually any 1972, 1973, and 1974 car models sold in the U.S., and you’ll see a noticeable change in bumper designs during that time. As the 1970s progressed, new vehicle designs used filler panels that more successfully disguised how far bumpers protruded.

Caption for above photo: When 1974 model year regulations went into effect, some manufacturers such as MG took a different approach – using a rubber coating to add style across all surface areas of larger bumpers. (1974 MGB model shown)

It was during this time that automakers also began experimenting with plastic covers that surrounded or completely enveloped the more massive metal bumper structures. Beginning with the 1973 Chevrolet Corvette, they saw increased use on late-1970s Porsches, Camaros, Firebirds, BMWs, and more.

It’s interesting to note that what we take for granted as today’s wraparound plastic bumper cover (which runs around the vehicle from one wheel well opening to the other) did not appear as a design feature until the new-for-1980 Mercedes S-class debuted. Before then, plastic bumper covers were merely end caps that did not extend to wheel well openings. The 1983 Honda Prelude was next to use wraparound bumper covers, and by the end of the 1980s they had eclipsed plastic end caps as the predominant style.

Wraparound bumper covers that have become the norm today were first introduced as a design feature on the new-for-1980 Mercedes S-class. This was quickly imitated, and plastic end caps that had been used up until then were slowly phased out by other manufacturers.

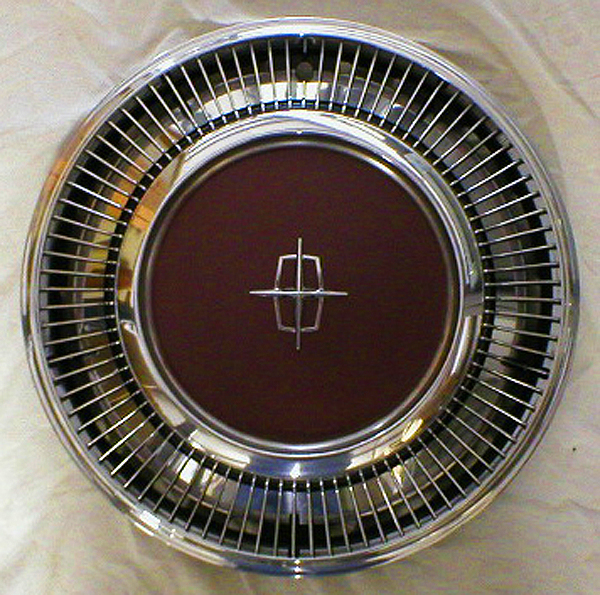

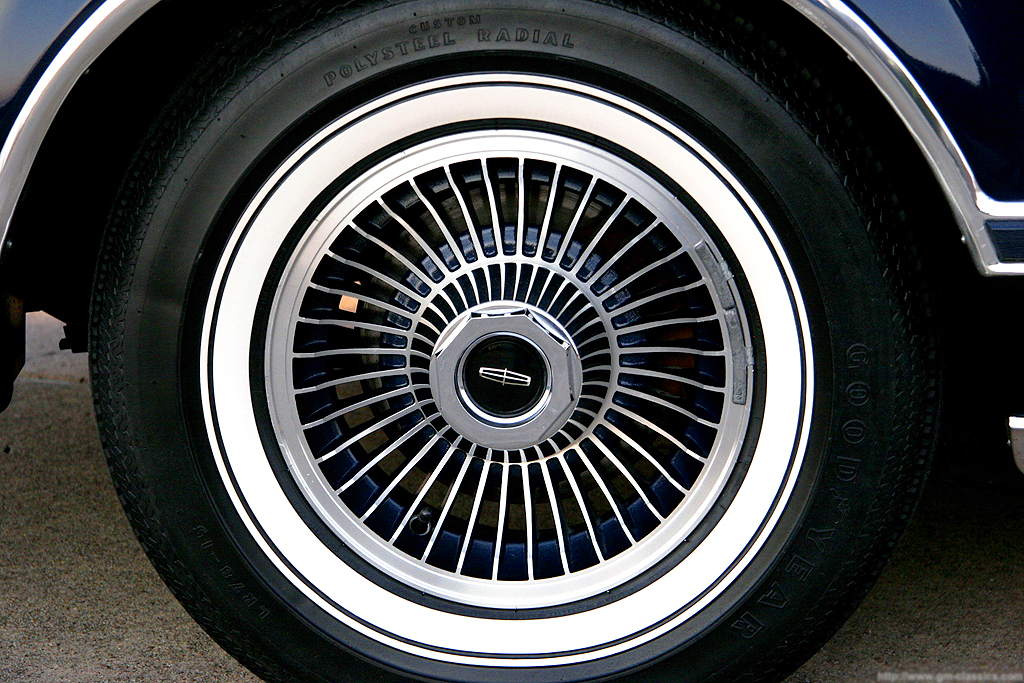

By the end of the 1980s, traditional exposed steel bumpers had been phased out in favor of wraparound plastic bumper covers. Shown here is a 1992 Cadillac Fleetwood Brougham, the last U.S. market production car (besides pickups and SUVs) to wear traditional metal bumpers.

Traditional steel-and-chrome exposed bumpers saw continued use through the 1980s on American vehicles nearing the end of their design cycles. After 1991 Ford LTDs and 1992 Cadillac Fleetwood Broughams went out of production, the only vehicles for sale on the U.S. market with traditional chromed steel bumpers were pickups and sport utility vehicles.

SAVINGS IN WEIGHT AND FUEL

Behind plastic bumper covers on most modern vehicles is a smaller, lighter bumper bar made of steel or aluminum, as seen on this Porsche 911.

The weight of a medium to large-size traditional steel bumper averages around 35 pounds each, compared to 10 pounds for an equivalent plastic bumper cover – totaling a weight saving of up to 50 pounds per vehicle. Considering the EPA calculates a 100 pounds weight reduction on an average-sized passenger car can lead to fuel economy savings of 1 to 2%, then losing two steel bumpers leads to a small but worthwhile gain. Depending on the overall weight of your vehicle, a reduction of 100 pounds leads to improved performance equivalent to gaining 10 – 20 horsepower.

REPAIRING CRACKS IN PLASTIC BUMPER COVERS

Items needed: 2-part automotive epoxy, mesh tape, repair kit with sandpaper, glaze putty, and paintwork touch-up items

If cracked edges of a bumper cover can be held together reasonably well by tape such as the one in this photo, give repairs a try – otherwise replacing the bumper cover is a more logical solution.)

If a bumper cover is cracked to the point where it has trouble holding itself together, it’s structurally compromised and should be replaced. However, a single crack that isn’t extensive can be repaired. Small holes or punctures can be filled but larger ones take experience to repair. If cracked edges can be held together reasonably well by tape, give repairs a try – otherwise replacing the bumper cover is a more logical solution.

For this procedure, bodywork experts recommend mesh tape and quick-drying automotive epoxy that mixes by hand before applying. Bondo filler used for rigid metal body panels should not be used because it has no flexibility and can crack when temperatures drop or plastic flexes.

After removing the bumper cover from your vehicle (see “Replacing a Bumper Cover” below), use a Dremel drill with a small rotating wheel to cut grooves in the crack on both sides. After that, sand three to four inches on both sides of the crack on the inside surface with 80 grit sandpaper to create surface texture that epoxy will adhere to best. Line up the cracked sections and apply mesh tape on the inside of the bumper cover to hold things in place along with masking tape on the outside surface. Apply the epoxy, using a finger to push it into the crack so that it oozes through to the front side thoroughly.

After 20 minutes when the epoxy has set (check specific instructions on epoxy container), remove the masking tape from the outside surface. When the epoxy underneath is fully hard to the touch, sand the outside with 80- or 100-grit sandpaper. Apply glaze putty to fill any pinholes then continue dry sanding with 180- and 320-grit sandpaper. To create a final smooth surface before applying primer and paint, wet sand with 800-grit sandpaper.

After 20 minutes when the epoxy has set (check specific instructions on epoxy container), remove the masking tape from the outside surface. When the epoxy underneath is fully hard to the touch, sand the outside with 80- or 100-grit sandpaper. Apply glaze putty to fill any pinholes then continue dry sanding with 180- and 320-grit sandpaper. To create a final smooth surface before applying primer and paint, wet sand with 800-grit sandpaper.

REPAIRING BUMPER COVER CHIPS OR SCRATCHES WITH TOUCH-UP PAINT

For unsightly scratches or paint chips in your bumper cover, touch up paint and wet sanding can create a nice-looking fill in many cases. After cleaning the chipped or scratched area, apply paint inside the area as well as over the edges of it because the paint will contract after drying.

For unsightly scratches or paint chips in your bumper cover, touch up paint and wet sanding can create a nice-looking fill in many cases. After cleaning the chipped or scratched area, apply paint inside the area as well as over the edges of it because the paint will contract after drying.

With water on top of the paint, use a fine 2000-grit to smooth touch-up paint until it’s flat and level with rest of the bumper cover. Buff the area using a medium weight buffing compound and a soft terry cloth towel. Repeat for three to four buffing and wipe-off cycles until you’re satisfied with the results. Then apply a last-stage protectant and wipe it off as directed.

With water on top of the paint, use a fine 2000-grit to smooth touch-up paint until it’s flat and level with rest of the bumper cover. Buff the area using a medium weight buffing compound and a soft terry cloth towel. Repeat for three to four buffing and wipe-off cycles until you’re satisfied with the results. Then apply a last-stage protectant and wipe it off as directed.

REPLACING A DAMAGED BUMPER COVER

Items needed: flat wrenches, socket wrenches, rivet gun (on certain vehicle applications), screwdriver, torx head bits (if applicable)

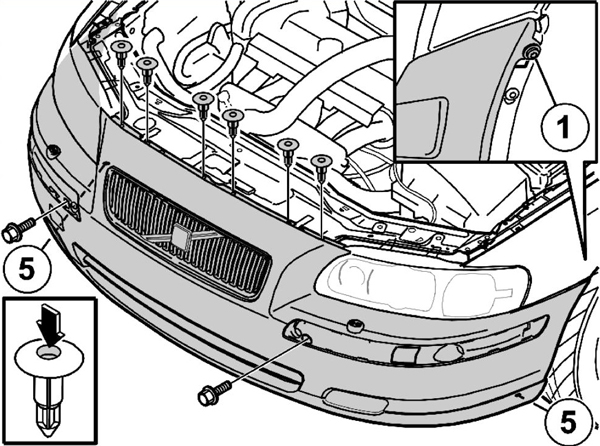

Replacing a plastic bumper cover is relatively easy because most are designed to unbolt and slide off with basic hand tools. You’ll notice bolts securing front bumper covers are typically right where you’ll see them easily after opening the hood, underneath the vehicle where they meet splash shields, and close to the edge of wheel well openings where the bumper cover meets the wheel well liner. If there are flat plastic caps or clips, remove them with a small flathead screwdriver by wedging up.

This illustration shows the typical locations of bolts and hold-down clips that need to be removed in order to take a front bumper cover off. Fasteners for rear bumper covers may need to be accessed through the trunk after removing one or more cover panels.

Remove the bolts with an applicable socket wrench or flat wrench. In the event your vehicle manufacturer has used rivets to secure things, they’ll need to be drilled out with a traditional drill. Then you’ll need a rivet gun to reinstall new ones – not an expensive purchase, but the proper tool to use for ensuring parts stay safely on. When drilling out rivets, bits designed for drilling into metal are most suitable due to a higher heat rating. Rear bumper covers will detach in a similar fashion as front ones, with some fasteners requiring access through the trunk after removing cover panels.

Many bumper covers are designed to slide horizontally along special brackets mounted underneath before coming completely loose. Perform final removal with care.

Once all fasteners are removed, the bumper cover can be detached. Many are designed to slide horizontally along special bracket pieces mounted underneath before coming completely loose, so move the bumper cover in this fashion first if you aren’t able to obtain specific instructions on your make and model. Save all fasteners because replacement bumper covers do not provide new ones. You’ll also want to note if your original equipment bumper cover has any separate molding trim strips, step pads, or aerodynamic pieces – and whether they can be salvaged or need to be replaced. These parts are not included with replacement bumpers either.

BUYING REPLACEMENT BUMPER COVERS

All manufacturers of bumper covers sell them in unpainted form – usually in bare black plastic without grille pieces. It’s important to remember that bumper covers for the same make, model, and year may differ in shape depending on bumper-mounted options your vehicle may or may not have. If your bumper has cut-outs for fog lights or parking sensors because you’ll want to make sure a new one matches all equipment and fits properly. Most newer vehicles have small removable caps known as “tow hook covers” on the front of the bumper covers. You’ll want a new bumper cover built with these because metal hooks bolted to the frame of the vehicle are behind them for pulling the vehicle onto a flatbed towtruck.

We won’t get into discussing how to prime and paint a bumper cover in this article. If you are considering doing your own paintwork, observe if the paint color on the body of your vehicle has faded due to age, sun exposure, or a from certain colors being more prone to discoloration than others. Fresh paint in your exact OEM color code may create a mismatch with the rest of your vehicle. Professional body shops can mix paint to factor in for color changes that naturally occur.